Wählen Sie Ihr Land:

Choose your country:

Wybierz swój kraj:

Choose your country:

Choose your country:

Välj språk:

Choisissez votre pays:

選擇您的國家

Based on your browser language, we recommend the following version of this page:

Basierend auf Ihrer Browsersprache empfehlen wir die folgende Version dieser Seite:

Based on your browser language, we recommend the following version of this page:

W oparciu o język przeglądarki zalecamy następującą wersję tej strony:

Based on your browser language, we recommend the following version of this page:

Based on your browser language, we recommend the following version of this page:

Baserat på ditt webbläsarspråk rekommenderar vi följande version av denna sida:

En fonction de la langue réglée dans votre navigateur, nous vous recommandons la version suivante de cette page :

The energy generated by your offshore wind turbine can only reach land if the underwater systems close to the turbine and the cables leading out are free of damage. Keeping these components free of damage not only ensures the functionality in the short term but is also extremely important for the availability of your wind turbines in the long term. All foundation-related components must be checked regularly in order to maintain the viability of lifetime extension for the offshore wind farm beyond the regular service life of 20 years. At the same time, underwater inspections are necessary to fulfil mandatory official requirements regarding the structural integrity of your offshore systems.

The weather, movement of the water, organic growth and constant wear and tear make carrying out the inspection a significant challenge because 95% of the cabling and foundation of your wind turbine or substation is not visible to the naked eye. Our concept goes beyond simple maintenance for accessible and difficult-to-access areas. We create technical and financial recommendations for you on a short-term and long-term basis and carry them out, if required. By taking your point of view as an operator, we see your offshore wind farm as a holistic project and categorise our subsea services in a comprehensible way. This enables you to make informed decisions about measures that might need to be taken.

To the video

YouTube Video

By playing the video, you agree to our privacy policy. If you play the video, data will be transmitted to the respective provider.

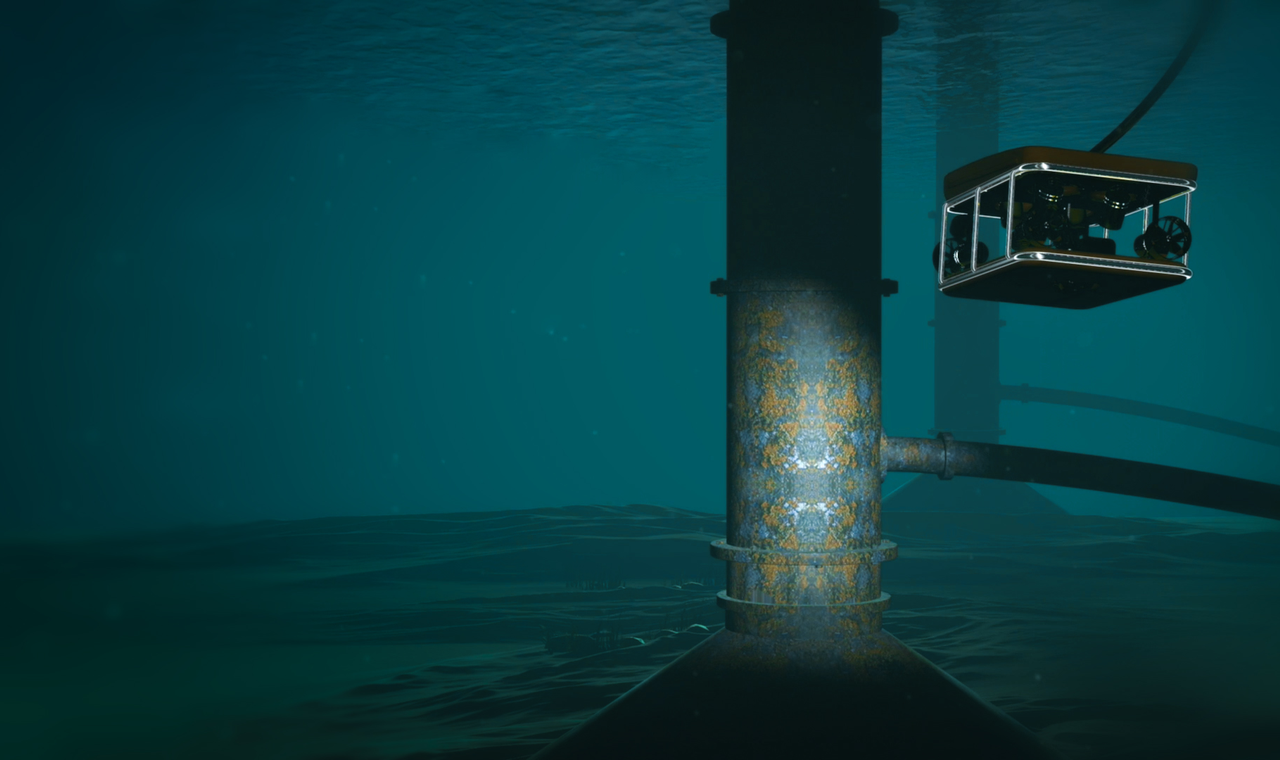

The first step in a well-designed subsea inspection campaign is visual inspection. This is then followed by an evaluation of the underwater images. The visual inspection provides information about superficial scratches and cracks on the inside and outside of the foundation of your wind turbine, the position of the cable harnesses and the cable entry points. The equipment includes state-of-the-art ROVs (Remotely Operated Vehicles). These ROVs can be launched from your vessel or ours and are remotely controlled via cable for visual inspections under water. This makes the expensive deployment of divers in the early project phase unnecessary. The important elements of the underwater inspection process at your offshore wind farm include, for example, various methods of corrosion protection (CP) including impressed current cathodic protection (ICCP), sacrificial anode measurements, methods for finding marine growth, weld seams, external and internal damage, sonar transponder and cable systems and cable protection systems (CPS). Our underwater inspections are an important part of the profitable implementation of your wind farm project because they help to ensure optimal performance of each of your turbines.

The ocean floor is subject to natural changes due to currents, weather and erosion, and objects floating around on the surface or moving around under water pose a threat to the integrity of the foundation of your wind turbine. To ensure the stability and long-term functionality of your wind turbines, we use our multibeam echosounding equipment (MBES) to examine the seabed and scour around your wind farm. Our team uses ultrasound technology, side-view sonar as well as magnetic and radar-based technology.

Some of the underwater components and connections of your wind turbine are extremely small or sensitive. Among other things, this applies to the extremely important power cables. They must be examined with extreme caution, and if they are damaged, they need to be repaired underwater. Where our MBES reaches its limits, we use an experienced team of divers from our network who are trained to examine these special structures. We are flexible and save costs in every situation: We commission the exact services that are needed at the moment they are needed.

To the video

YouTube Video

By playing the video, you agree to our privacy policy. If you play the video, data will be transmitted to the respective provider.

We create offshore clusters by combining similar work at multiple wind farms, and this enables us to save time and resources and to distribute the project costs between several clients. This means that you not only receive high-quality service at an economical price, it also helps to protect the environment by saving a considerable amount of fuel that the vessels would have otherwise burned. Nevertheless, our cluster implementation plan ensures a solution that is tailored to your wind farm, based on your specific logistical requirements, your project goals and the local environmental conditions.

The Offshore Wind Journal reported on the modern service structures of our cluster strategy.

Would you like to find out whether your wind farm can also benefit from our subsea services or request a quotation?