Nicolas and Markus, what is the goal of your project?

Our goal is to provide our technical departments with recommendations for action relating to the maintenance of wind turbines, to identify the components that need to be taken along on service deployments and to automatically pass on information that the departments can work with independently. Ultimately, this results in improved efficiency and performance of the wind turbines, optimally timed maintenance and the fast availability of components. The unique feature of this project is that no additional sensors need to be installed on the system, which means that there are no costs for the operator.

How did you approach this task?

After completing our two master's theses on the subject and making the decision to develop this type of software in-house, we had discussions with our technical department and received lists of errors for which timely prediction would be of benefit. We then checked what data we have and what we are missing. This is based on data from more than 300 wind turbines of a given type from the last five years. The first algorithms that we developed are currently being tested. This should be completed at the end of June, and we expect that our models will pass the test phase with positive results. After that, they will be implemented in a software application and used in day-to-day business.

Can you give an example of a fault prediction?

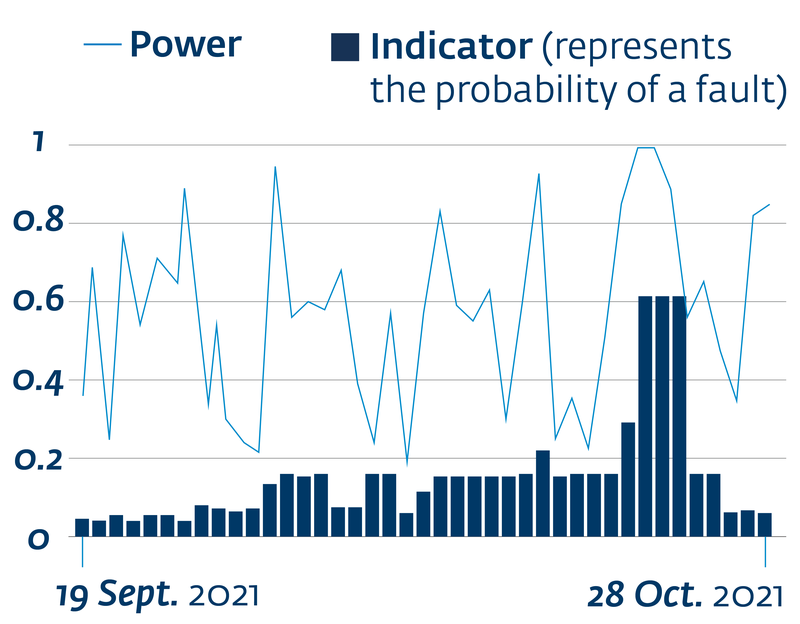

At the end of September, for example, a wind turbine was detected by our system in which the indicator (a value that represents the probability of a fault) exceeded a defined limit value (see illustration). A service order was then created and a team deployed to the turbine. As expected, the service team found a heavily soiled transmission oil cooler. After cleaning, it was then possible to observe how the indicator value subsided. Especially during the test phase, it is important for us to get information about the cause of the fault. For this reason, we are in close contact with the teams on site, who give us valuable feedback. This enables us to subsequently test and evaluate whether our predictions were correct.

How did you decide to develop the software yourself?

In-house programming has several advantages for us. We have all necessary competencies and personnel under one roof. Approximately fifteen employees provide support for the project with their expertise. This makes us flexible and fast because the lines of communication are short and we avoid time-consuming coordination with external providers.

And what are the next steps?

The funding from WTSH will run until October 2022. The project will definitely continue after that, and we intend to continue to expand the range of models for predictive fault detection. New tasks, such as the development of a platform for presenting the results, have already been added to the project plan. In addition, being able to access and analyse the data allows us to develop further internal data-driven processes in the future, and this can be used by employees and will constantly improve our service for operators.