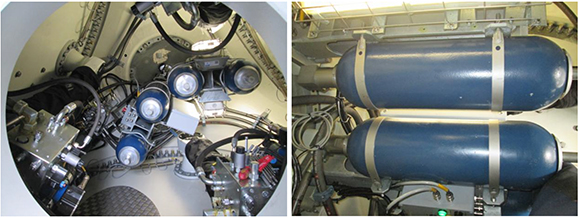

Pressure tanks in the nacelle and hub of wind turbines must be capable of withstanding severe stresses. They ensure that the hydraulic pitch regulator (blade adjustment) works, and they also fulfil emergency/safety functions related to the hydraulic disk and yaw braking system. If the pressure tanks malfunction, this can cause personal injury and material damage. For this reason, the Ordinance on Industrial Health & Safety stipulates mandatory inspection before commissioning as well as regular follow-up tests of the pressure tanks. Recently, some German federal state authorities have begun checking the turbine components (e.g. pressure tanks and service lifts) that require monitoring with respect to these aforementioned inspections. The manufacturer-independent service provider Deutsche Windtechnik is responding to this need and, in cooperation with TÜV Süd, will be offering pressure tank inspections for onshore wind turbines from the manufacturers AN Bonus, Siemens, Vestas and NEG Micon with pitch hydraulic systems in Germany.

What regulations apply?

Pressure tanks can not only corrode, they can also burst. When damaged, they pose an increasing danger to their surroundings because the pressure can turn parts that become detached into projectiles. The Ordinance on Industrial Health & Safety stipulates that pressure tanks in wind turbines must be inspected before commissioning. Internal and external follow-up inspections must be carried out at the latest after ten years. The state authorities have announced more rigorous monitoring with respect to performing inspections, because in the past they have been neglected throughout the industry. Expert appraisers and operators are increasingly focusing on the topic of wind turbine safety.

Non-destructive inspection concept

For this reason, Deutsche Windtechnik and TÜV Süd have jointly developed a non-destructive process that allows pressure tanks to be inspected on site. An ultrasonic device is used for inspecting the outer surface of the pressure tank. Removing and replacing the tanks is not necessary. The device detects even the smallest cracks in the surface of the tank. If necessary, the engineers can also do the risk assessment and commissioning inspection.

To a large extent, the failure to perform pressure tank inspections in wind turbines on a regular basis has been caused by major obstacles in the way of legally compliant implementation. Operators can now present an alternative inspection concept to the state authority upon request and submit a risk assessment including inspection intervals and items.

Maximum safety with lowered costs

The inspection concept that has been introduced not only addresses the safety of people and machines, which of course has top priority. The procedure also prevents consequential/long-term damage from causing additional costs, which can happen if the hydraulic pressure tank is not inspected.

The inspections usually do not take more than one working day to perform, depending on the scope. In order to avoid loss of earnings, we recommend scheduling the inspection appointment for the summer months or times when there is less wind.

Our quotation form makes the process quick and easy for you. If you have any further questions, please feel free to contact us:

Carina Soppa, Customer Support Advisor, Deutsche Windtechnik Service GmbH & Co. KG

C.Soppa@deutsche-windtechnik.com

+49 4845 79168 581