We asked André Hansen from Technical Customer Management at BGZ to tell us about the incident from his point of view as an interface coordinator between commercial and technical operations management at BGZ.

André, in the middle of negotiations for the new full maintenance contract for the Roter Berg wind farm, an extremely rare incident occurred. What happened?

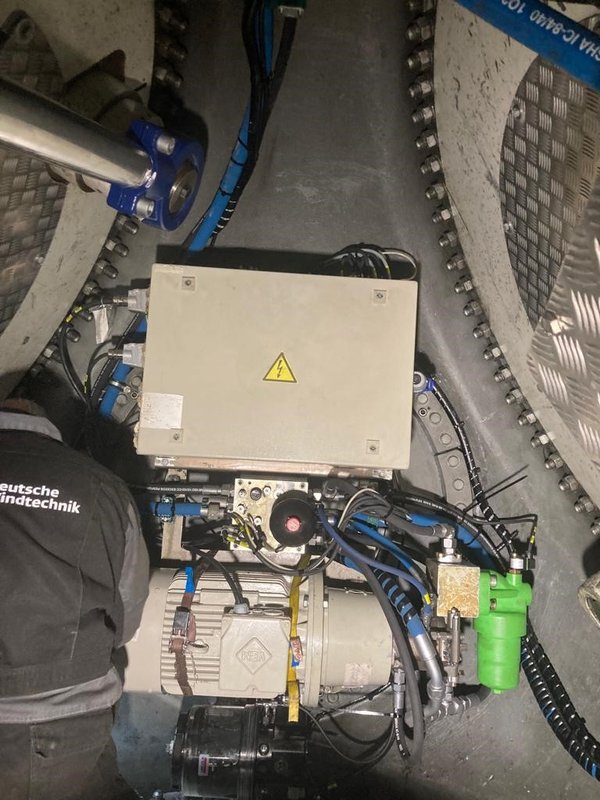

We had never experienced anything like it before: One of the motors of the pitch hydraulics had been torn off inside of the hub and had damaged everything in the hub due to the continuous rotation. It affected absolutely everything inside of the hub. It was like a huge washing machine drum with a couple of hundred kilos of material rolling around inside. The cause of the motor being torn off was sudden, catastrophic failure of the material of the base plate.

How did Deutsche Windtechnik become involved? The turbine was still being serviced by the manufacturer.

The manufacturer could have also done the work, but it was not able to get the necessary spare parts as quickly. Not only did the interior of the hub have to be completely cleaned but most of the components also had to be replaced. This included all three pitch cylinders, motors, control blocks, hoses, switching cabinets and much more. Since the change of contract was almost complete anyway, we asked Deutsche Windtechnik if they could go ahead and take care of it. Then everything went very quickly: The damage was assessed in mid-October, the work began on 1 November, and nine days later the turbine was put back into operation. The short period of time it took from our request to prepare an offer and then to complete the work was impressive.

How satisfied was BGZ with the technical handling?

Deutsche Windtechnik's technical expertise is a game changer for our older turbines. On the one hand, this is particularly true when it comes to the availability of spare parts. On the other hand, it is also extremely smart of Deutsche Windtechnik to draw upon the expertise of experienced technicians at its back office. The technicians have excellent training and extensive experience with these older types of systems.

What are your closing thoughts regarding the incident at the Roter Berg wind farm?

The work that was carried out at the Roter Berg wind farm was very well coordinated and went extremely smoothly. That was very good. We have transferred the responsibility for maintenance for many of the wind farms from the BGZ portfolio to Deutsche Windtechnik after the manufacturer's obligation to provide service expired. The Roter Berg wind farm was added in mid-November as part of a full maintenance contract including large components, and we are looking forward to further cooperation.