Wind turbines not only generate green energy, they also produce huge amounts of data around the clock. Experts distinguish between monitoring data and data related to the technical operating parameters. In addition, there is also what is known as diagnostic data. This is very high resolution data, usually in the 100th of a second range. Analysing this data can provide valuable insights into certain errors in turbine operation. But who owns all this data? The manufacturer or the owner of the turbine? Who decides who gets access to the data? And who has the expertise to analyse this data in a targeted manner and use it to improve turbine operation? In addition to the data, the ability to access the entire wind turbine and its various subsystems is crucial. Clarifying these questions requires the participation of the manufacturer as well as the system purchaser and/or operator. Service providers, technical operators and suppliers also play key roles. In addition to economic, technical and legal aspects, the socio-political side of things is also likely to become increasingly interesting.

The purchase contract determines access

"The topic is extremely complex, and this makes it difficult to form an opinion and find a solution," said Jasmin Škrijelj, Senior Manager Electrical Components. "The core of the issue is the restriction of the transfer of access rights, operating data and diagnostic data to the owner of the turbine. In principle, it is true that all operational data belongs to the owner of the system. But which data this specifically includes is then determined in detail in the purchase contract. However, whether these are the parameters that are required from a technical point of view to provide maintenance for the turbines is often beyond the owner's technical knowledge. This can have negative consequences for the owner. If, in the course of turbine operation, the owner is not satisfied with the manufacturer's service and decides to switch to an independent service provider or perform some of the service using its own staff, it only has a limited ability to do so. In addition, the owner is increasingly being denied access to certain special tools, which enables the manufacturer to solidify a monopoly on special repair work. Dependencies are deliberately being created here, to the detriment of competitive diversity in the service market."

Developing an early awareness of what will be needed later on for flexible service

Matthias Brandt, Director of Deutsche Windtechnik, said: "We want to raise awareness in the industry regarding the connections between turbine data access, competition and cost structures. It is important to us to not have tunnel vision regarding this situation. It's not just about individual manufacturers, operators or independent service providers. It is about nothing less than the successful investment of the operator in connection with the performance of the wind industry as a whole in the coming years and decades." In other European markets, things can be quite different. "In Spain, for example, the market is dominated by large international energy suppliers that also want to perform service tasks on their turbine inventories themselves. Because of their size and their extensive turbine portfolios, they are able to acquire the necessary expertise and negotiate very open contracts with the manufacturers on an equal footing.“

What does the owner of a wind turbine need in order to flexibly manage the operation of its turbine?

- Adequate turbine documentation

- Access to the turbines, including codes, dongles, tool kits and much more, as well as special software to enable error analyses and to eliminate errors

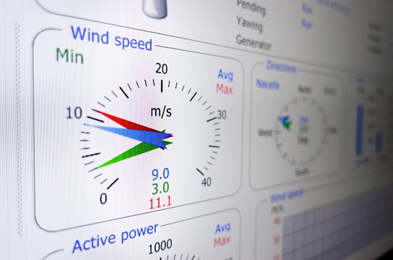

- Access to the SCADA system (System Control And Data Acquisition): This system stores data about turbine status messages, errors, yield data as well as other operating parameters such as rotational speed, power, wind speed and direction. The necessary access permissions to configure settings and make adjustments are often missing here.

- Access to special tools, in particular for replacing large components

The negotiation of the purchase contract is crucial

How do the restrictions on the transmission of technical operating data affect the daily service work at Deutsche Windtechnik? Matthias Brandt said: "Based on the SCADA data and depending on the degree of access to further technical operating parameters, we can record everything that is not blocked or encrypted. This depends on the individual turbine type and manufacturer, or, as described, on the existing access rights of the client. Our expectation is that our technicians and engineers can work on the turbines and ensure operation without having to depend on manufacturers. It is important to us to raise awareness among operators that the basis for ensuring that the risk of monopolisation by manufacturers does not escalate further is created when the purchase contract is negotiated. That would be a huge step backwards for the industry."